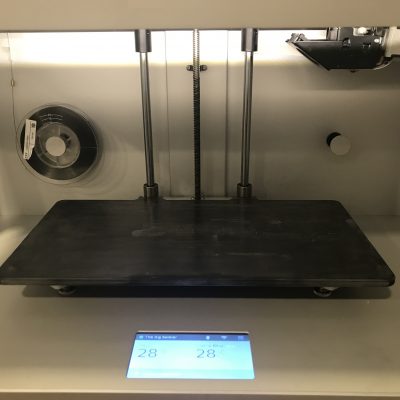

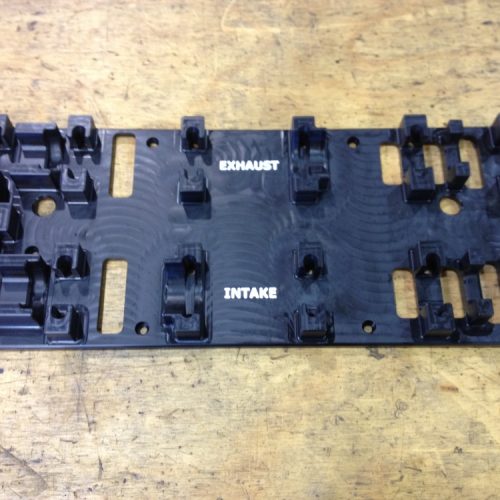

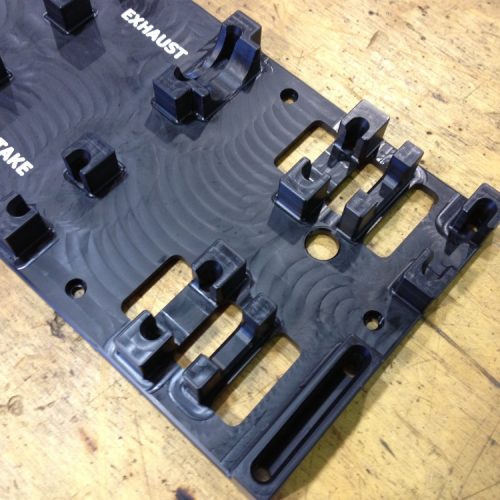

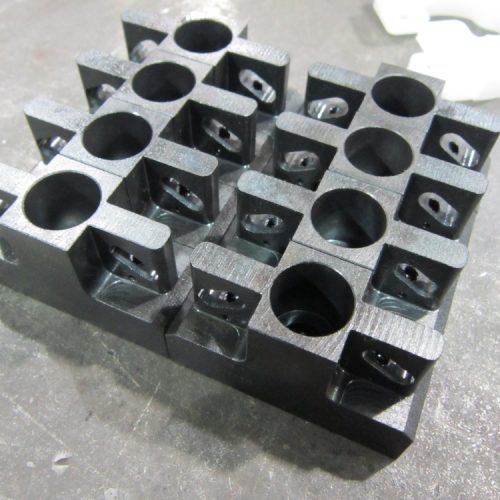

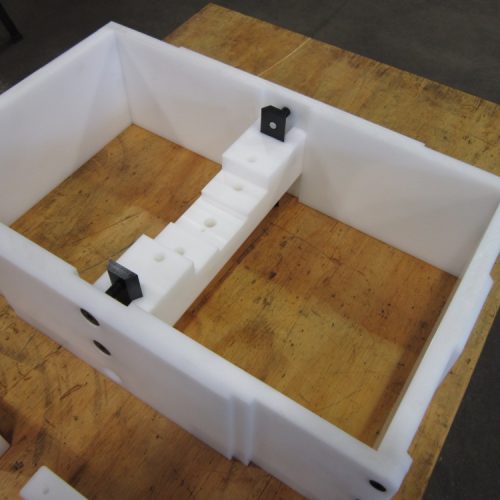

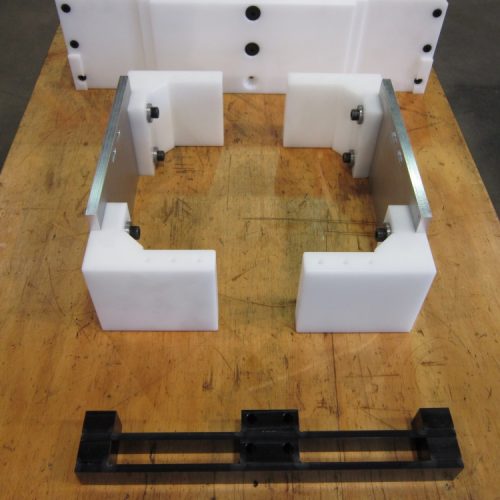

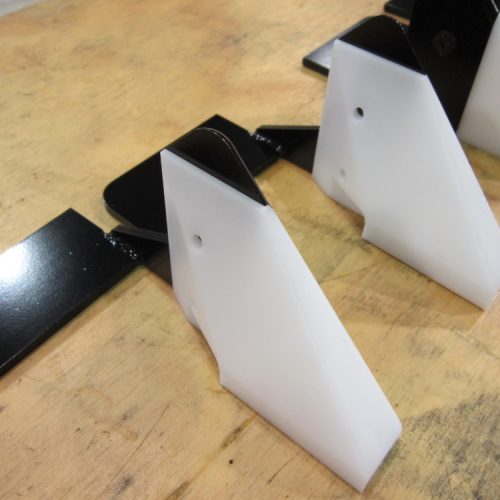

3D PRINTING

Our 3D Printer uses a continuous nylon mixed with chopped carbon fibre called Onyx Filament offering a high strength thermoplastic with excellent heat resistance, surface finish, and chemical resistance. Printing with continuous fibers allows us to produce parts which can be put into working environments and manufacture your prototypes quickly and efficiently. These robust 3D printed parts reinforced with, Carbon Fiber, Kevlar, Fiber Glass or High Heat Fiber Glass, can replace some machined metal parts.

What does this mean for you? Using your supplied CAD or our own designs from your requirements we can speed up the design and manufacturing processes. From start to finish we can be faster and more efficient to provide high quality 3D printed parts and prototypes for your projects.

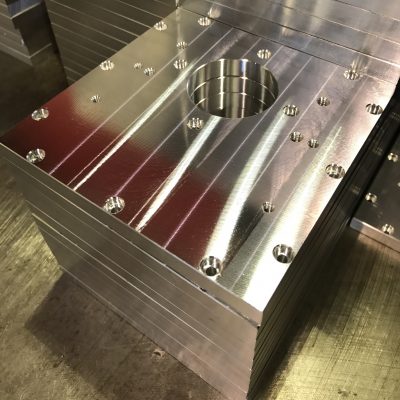

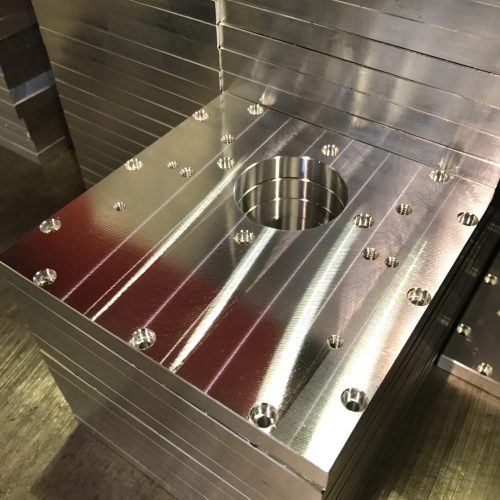

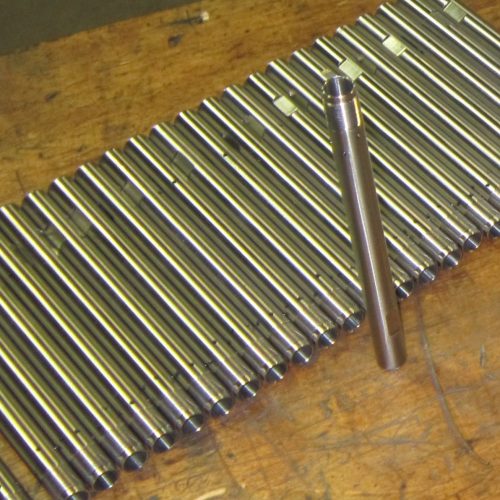

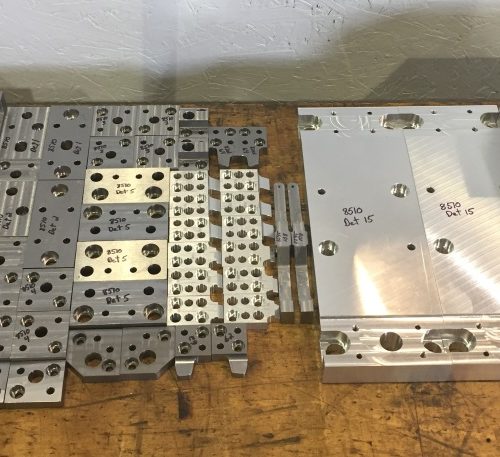

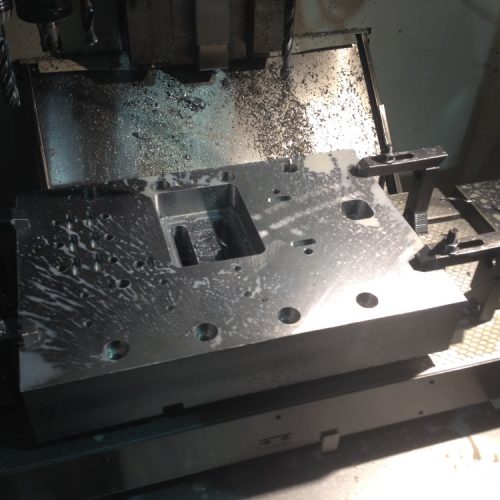

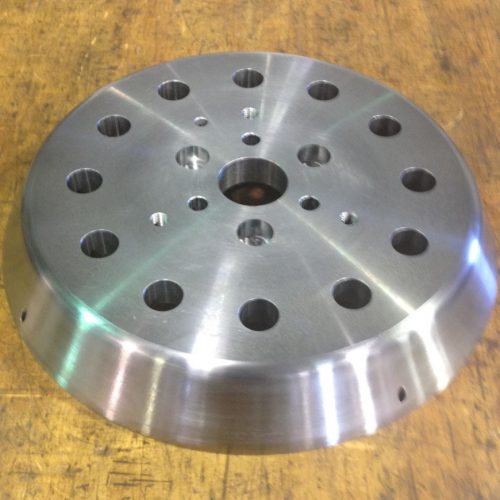

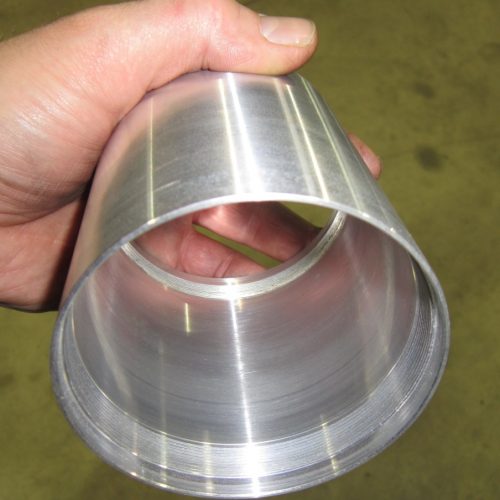

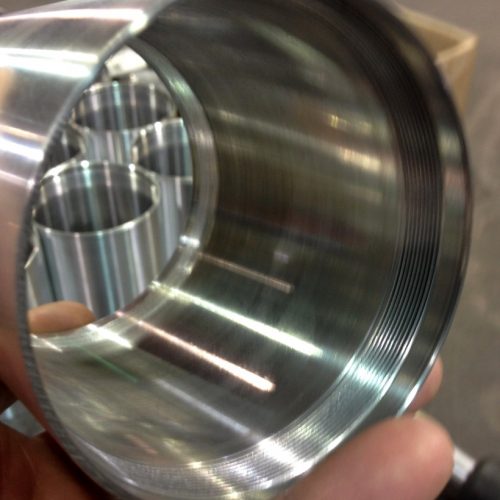

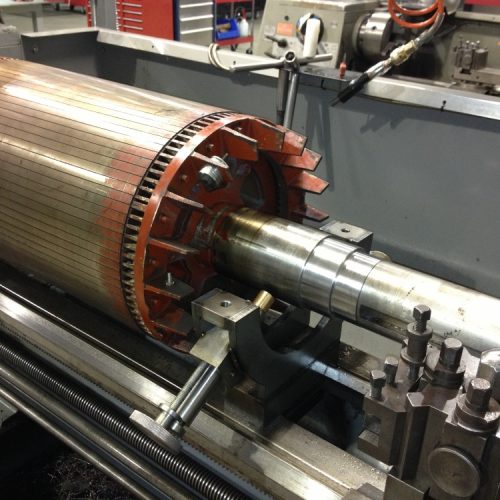

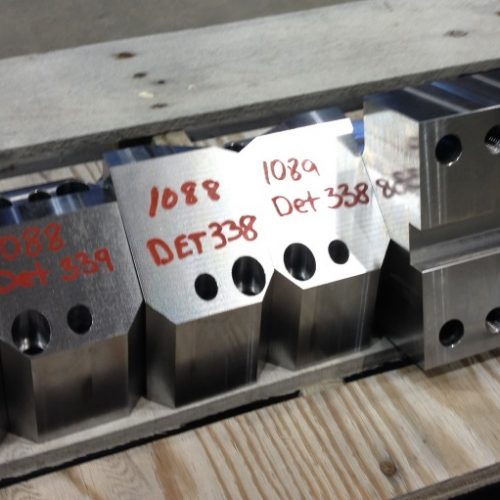

CUSTOM MACHINING

We are a full service machine shop with CNC milling and CNC turning capabilities. Custom Concepts Machining can custom design products or parts using the latest CAD software and then quickly move that design to part using Mastercam as our toolpath generation. This allows us to get our machines cutting parts quickly so in turn you get your finished product faster. We also have traditional manual machines for manual machine shop work including, milling, turning, sawing, and drilling operations.

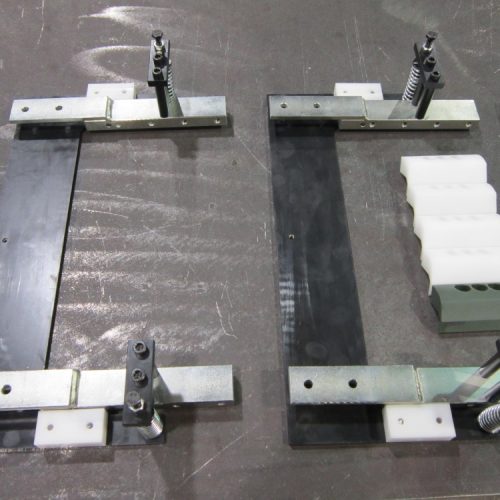

FABRICATING & WELDING

Custom Concepts Machining prides itself on being a full service shop. Experienced in Mig, Tig, and Arc Welding on steel, aluminum, stainless steel and also other materials, we can handle any job that requires welding or fabricating. From custom suspension parts to rod iron railings we can handle your fabricating or welding job.

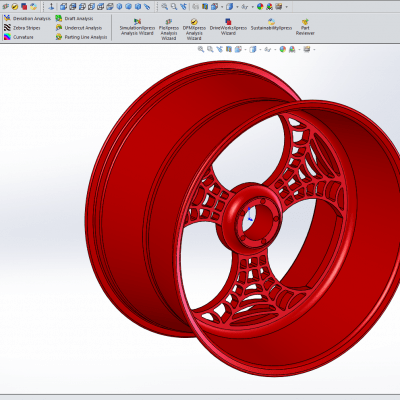

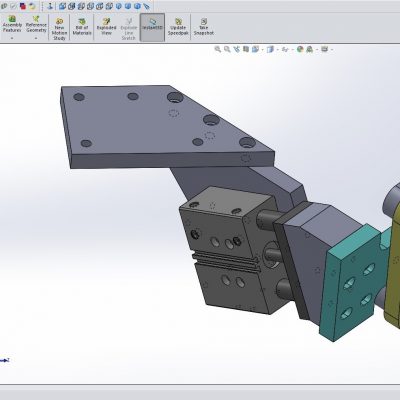

ENGINEERING

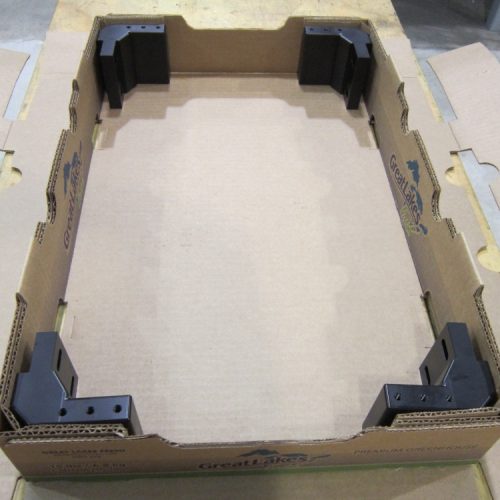

At Custom Concepts we have engineering capabilities using the latest CAD software. We can reverse engineer parts or assemblies to have a full 3D modeled rendering of the components or assemblies.

Having this capability allows us to see and understand what the parts or assemblies are for and how they work before we begin the manufacturing process.

This also allows us to have the capability to design and engineer our own parts and machinery for things like automated equipment and tooling.